Development of a screw extruder for extracting linseed oil from flax

DOI:

https://doi.org/10.24352/UB.OVGU-2024-058Keywords:

oil press, linseed, extruder, DEM, particle, bulk solidsAbstract

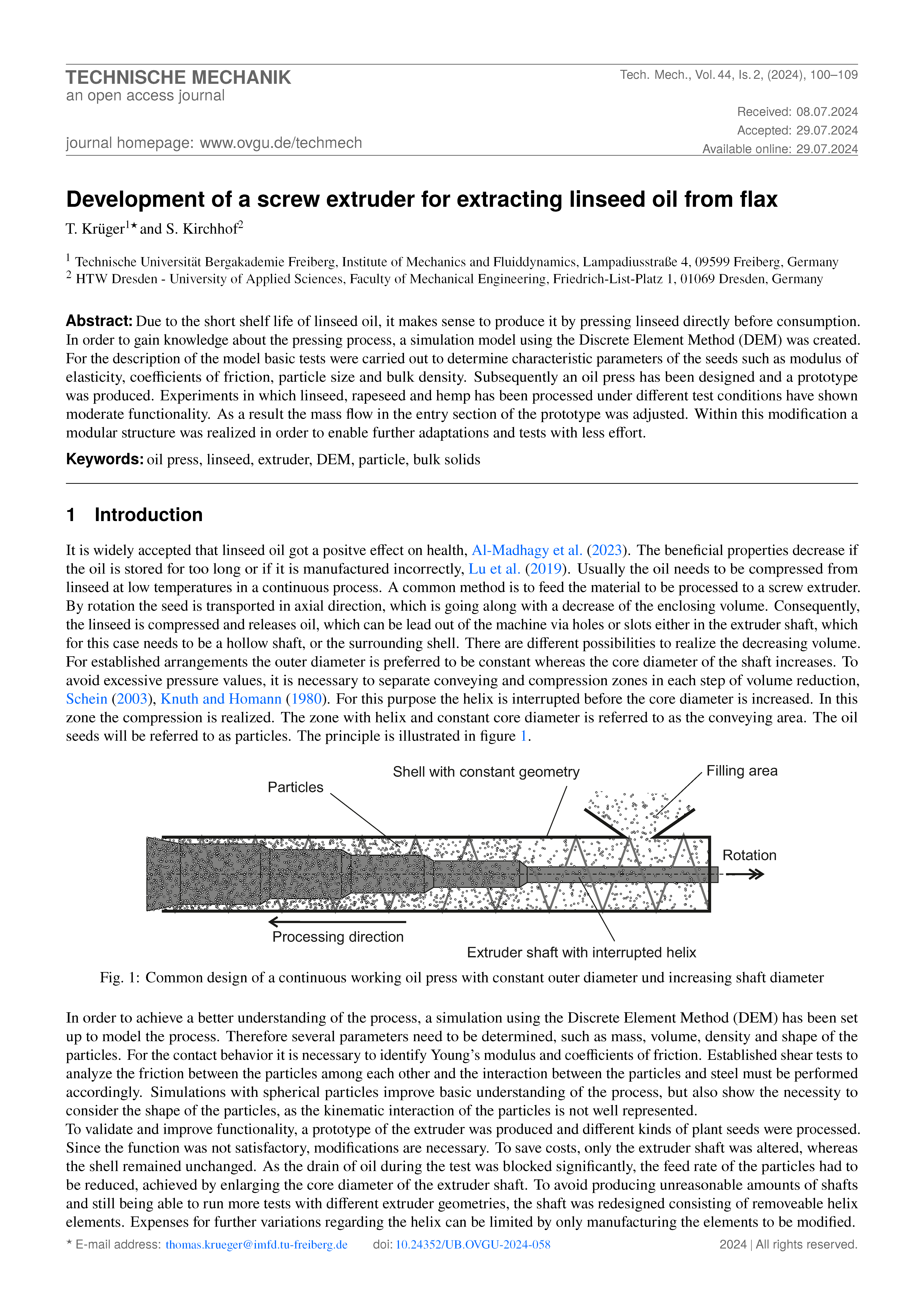

Due to the short shelf life of linseed oil, it makes sense to produce it by pressing linseed directly before consumption. In

order to gain knowledge about the pressing process, a simulation model using the Discrete Element Method (DEM) was created.

For the description of the model basic tests were carried out to determine characteristic parameters of the seeds such as modulus of elasticity, coefficients of friction, particle size and bulk density. Subsequently an oil press has been designed and a prototype

was produced. Experiments in which linseed, rapeseed and hemp has been processed under different test conditions have shown

moderate functionality. As a result the mass flow in the entry section of the prototype was adjusted. Within this modification a

modular structure was realized in order to enable further adaptations and tests with less effort.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Thomas Krüger, Stephan Kirchhof

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.