Calculation of Torsional Vibrations and Prediction of Print Quality in Sheetfed Offset Printing Presses

DOI:

https://doi.org/10.24352/UB.OVGU-2017-094Abstract

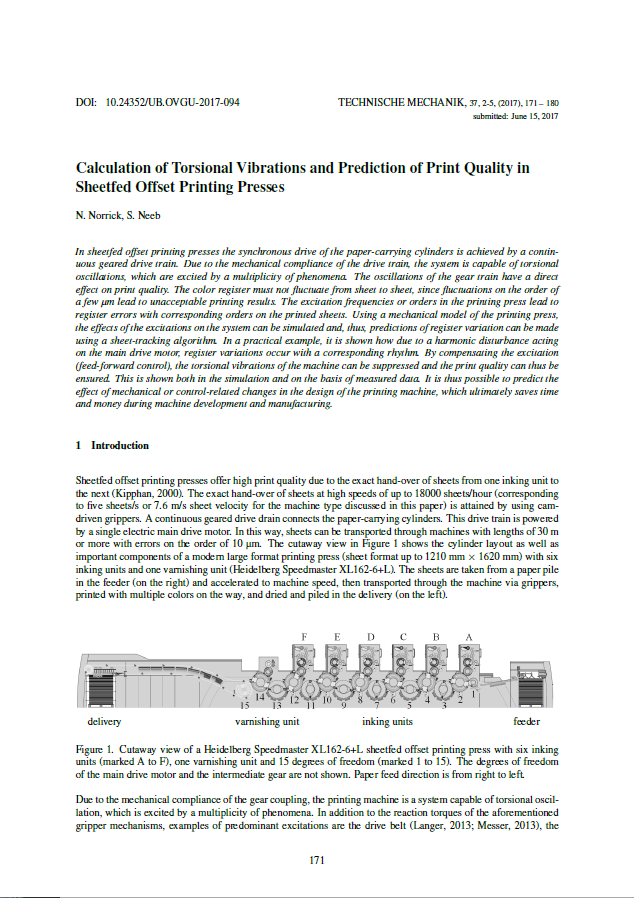

In sheetfed offset printing presses the synchronous drive of the paper-carrying cylinders is achieved by a continuous geared drive train. Due to the mechanical compliance of the drive train, the system is capable of torsional oscillations, which are excited by a multiplicity of phenomena. The oscillations of the gear train have a direct effect on print quality. The color register must not fluctuate from sheet to sheet, since fluctuations on the order of a few μm lead to unacceptable printing results. The excitation frequencies or orders in the printing press lead to register errors with corresponding orders on the printed sheets. Using a mechanical model of the printing press, the effects of the excitations on the system can be simulated and, thus, predictions of register variation can be made using a sheet-tracking algorithm. In a practical example, it is shown how due to a harmonic disturbance acting on the main drive motor, register variations occur with a corresponding rhythm. By compensating the excitation (feed-forward control), the torsional vibrations of the machine can be suppressed and the print quality can thus be ensured. This is shown both in the simulation and on the basis of measured data. It is thus possible to predict the effect of mechanical or control-related changes in the design of the printing machine, which ultimately saves time and money during machine development and manufacturing.