Hybrid Metal Foams

Experimental Observations and Phenomenological Modelling

DOI:

https://doi.org/10.24352/UB.OVGU-2017-050Abstract

Metal foams are a very interesting class of microheterogeneous, cellular, lightweight materials which are often used as kinetic energy absorber. In this study open cell metal foams consisting of a 3D network of interconnected pores have been coated with nanocrystalline nickel via an electrodeposition technique. The resulting hybrid foams were submitted to several uniaxial and biaxial tests, where not only the stress-strain response but also the energy absorption capacity, size effects and damage behaviour were investigated.

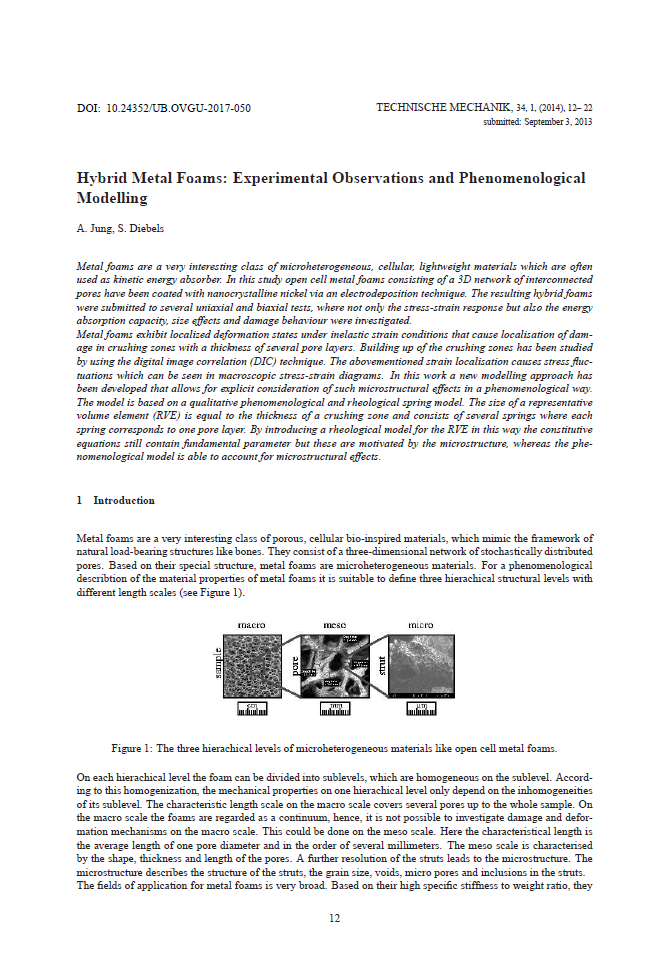

Metal foams exhibit localized deformation states under inelastic strain conditions that cause localisation of damage in crushing zones with a thickness of several pore layers. Building up of the crushing zones has been studied by using the digital image correlation (DIC) technique. The abovementioned strain localisation causes stress fluctuations which can be seen in macroscopic stress-strain diagrams. In this work a new modelling approach has been developed that allows for explicit consideration of such microstructural effects in a phenomenological way. The model is based on a qualitative phenomenological and rheological spring model. The size of a representative volume element (RVE) is equal to the thickness of a crushing zone and consists of several springs where each spring corresponds to one pore layer. By introducing a rheological model for the RVE in this way the constitutive equations still contain fundamental parameter but these are motivated by the microstructure, whereas the phenomenological model is able to account for microstructural effects.